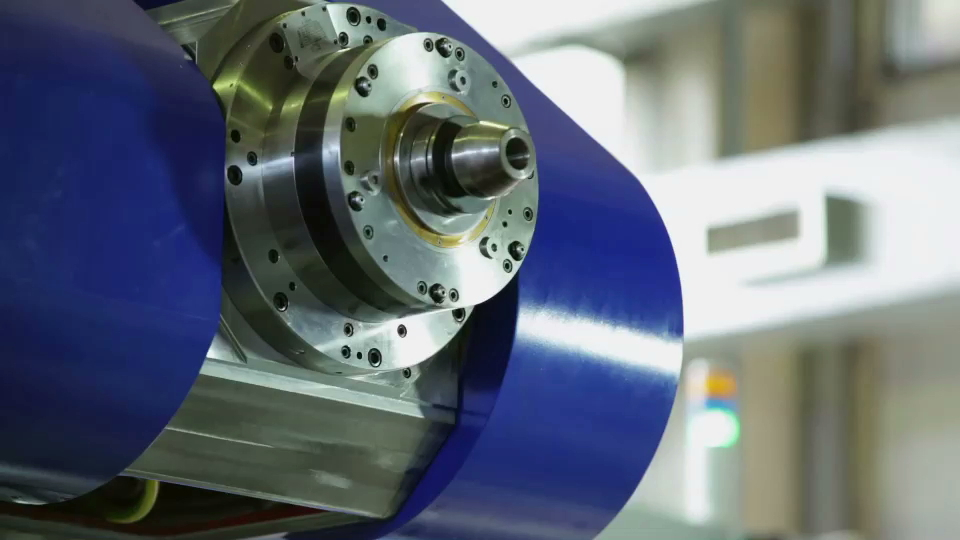

Thanks to sophisticated sensors located in all the areas subject to wear (motors, bearings, ball-screws, rollers, actuators) and to the connection to a powerful network capable of hosting and processing a large amount of data in real time (Big Data Analytics), Mandelli HMCs can send a continuous flow of information on their working conditions. A Cloud Computing system collects the data from different Mandelli HMCs all over the world and compares the components mathematical models with the statistics about failures, thus identifying the right combinations of measurements and values which determine a highly probable downtime in the next 24 - 48 hours.