Spark Ti 2100 – Options

Spark Ti 2100

Measuring probe

The 3D measuring proble available on our HMCs is very compact and can be employed in the hardest working conditions. It is automatjically loaded by the tool magazine where it is housed and its efficient radio transmission system guarantees the work-piece geometrical data to be transmitted fast to the NC.

Spark Ti 2100

Facing Head System

It is our application concerning the 5th axis facing head. On the top side of the head it is also available an NC-controlled motorization transferring the movement to the sliding bars. The motorized heads are automatically loaded from the tool magazine.

Spark Ti 2100

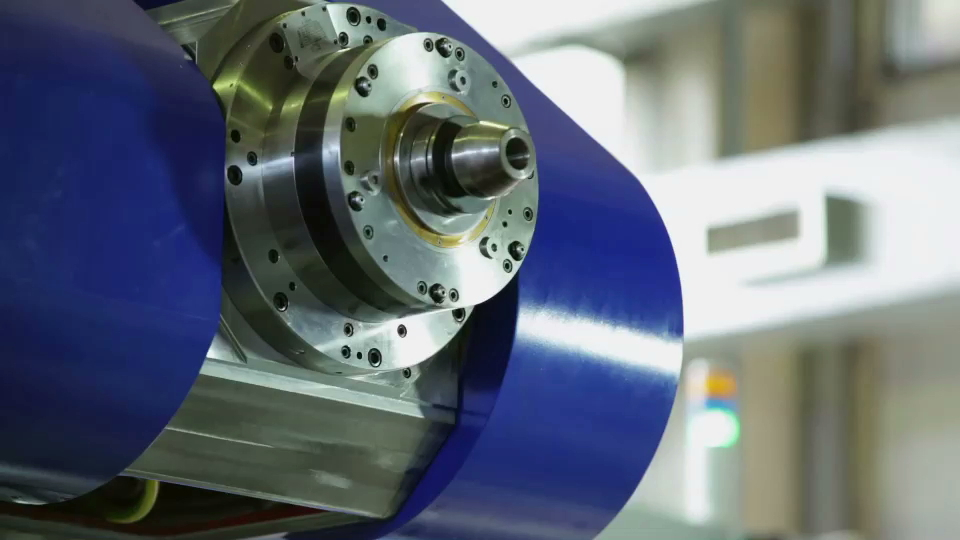

Turning Head

A head extension for turning internal operations, thanks to which it is possible to reach a 600 mm depth, is applied onto the head with a fast and reliable automatic change. It is also possible to have the automatic tool change directly on the head.

Spark Ti 2100

Tool Integrity Control

It is a direct contact tool integrity sensor mounted on the rack tool magazine which allows tools to be controlled in concealed time.

Spark Ti 2100

Air filter extractors

It is the aspiration system extracting the fumes generated by the pressurized coolant. The aspiration occurs inside the HMC box and it is extremely important to protect the working area but mainly the operator's health.

Spark Ti 2100

Laser tool presetting

The tool control unit is tightly assembled onto the HMC base to guarantee the maximum measuring accuracy. Its position, which has been specifically studied, allows for full mobility within the work area. The laser transmitter and the receiver are installed in a clean area outside the box and a robust cover ensures maximum protection against accidental crashes.