At Mandelli the future comes before, since more than 80 years

We started in 1932 and we never stopped. Today it is our firm intention to continue to promote the development of the technology for the future. We are proud to be leaders in the global market.

1932

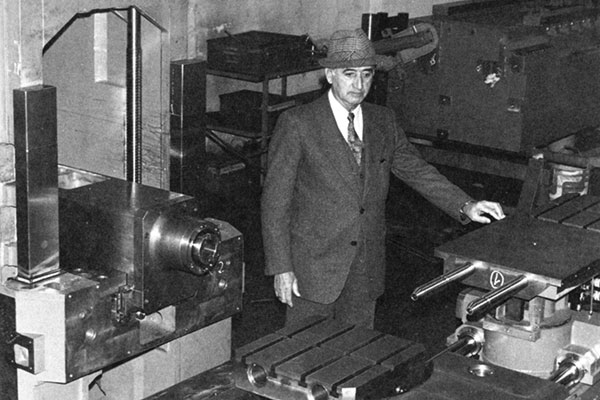

In 1932 Renato Mandelli founded a sole proprietor company for precision machining of mechanical parts

In 1960 the founder associates his sons Sante, Giancarlo and Umberto in the business and the company becomes Officina Mandelli Snc

Giancarlo will manage the company from the early 70s until the early 90s

1965

Realisation of the first machine tools, POSITIV, MEDAL, THEMA and building of the first unit of the present plant

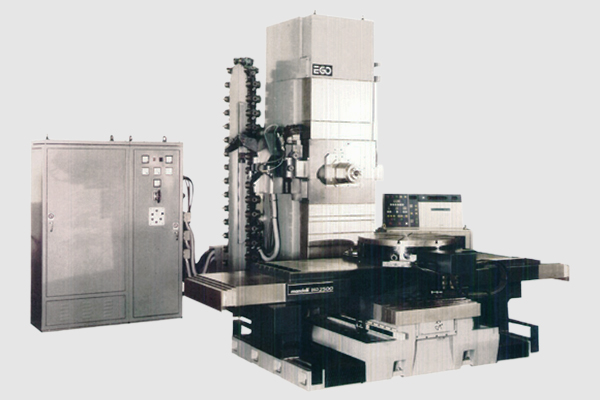

Production of the first machine with the features of a machining center, EGO. It becomes a limited company

1970

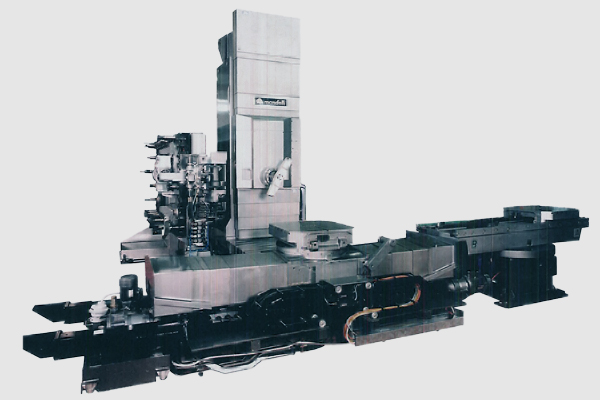

Introducing the new REGENT line, a modular generation that can be integrated into a generation and integrated modular into more complex systems

The first machining experience on special materials typical of the aviation industry such as titanium

1975

Two sales offices and direct service are established in France and Germany, Mandelli GmbH in Wiesbaden and Mandelli France outside Paris

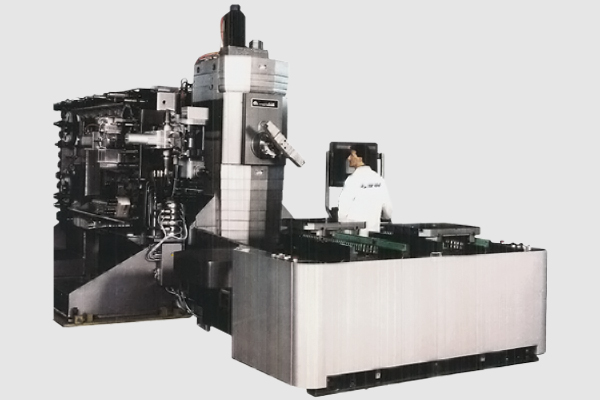

Producing of the first flexible manufacturing system and development of activities called "FMS"

1980

Stipulation of production license agreement between Mandelli and Amada - Japan

Development of an NC called Plasma

Design and realization of a new machining center called QUASAR designed by the famous architects Ettore Sottsass and Matteo Thun

1985

The new generation of M range products

Mandelli was put on the Stock Exchange on December 18, 1989

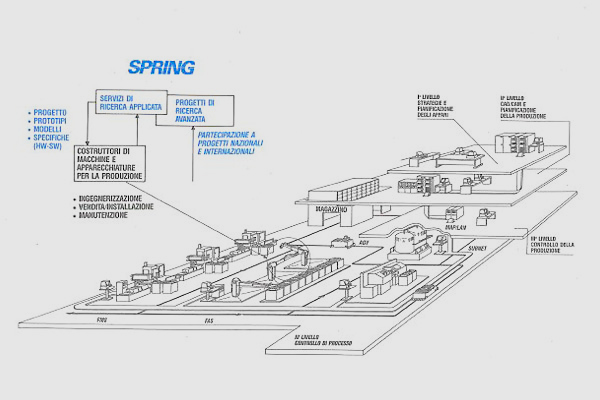

Spring is established, a joint venture with IBM Italy SpA for research activities

1990

New subsidiaries in England and the USA are established

The serious world crisis of 1993 causes Mandelli’s insolvency. The company enters into temporary receivership

In January 1994 Dr. Giancarlo Mandelli dies for a serious illness. He led the company for over twenty years

1995

In 1994 Mandelli comes out of receivership and is acquired by a group of Italian entrepreneurs

In May 1995 the new lines of medium and large size STORM and ROCK Machining Centers are presented at EMO Milan

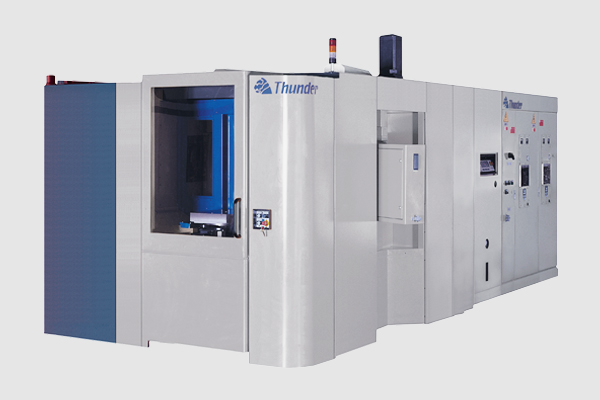

At the end of 1998 the new line of THUNDER machining centers, ideal for precision machining operations and high productivity is presented

2000

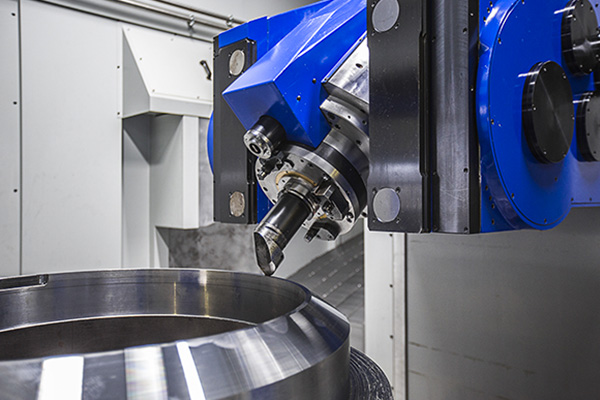

Under the new leadership, a new line of 5-Axis Horizontal Machining Center is developed: SPARK X Line

The SPARK X revolutionizes the traditional concept of the machining center with three linear axes of movement on one side and the workpiece on the other

2005

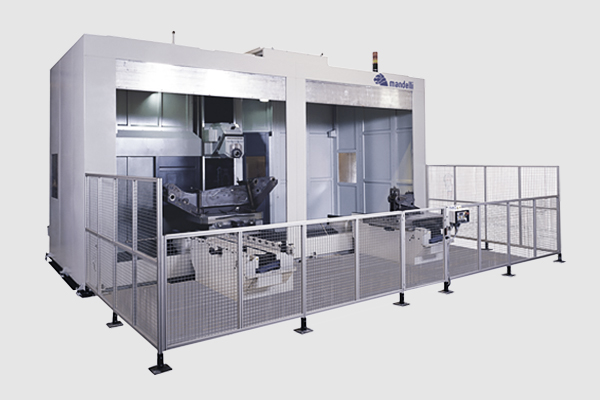

In 2005, the new line of fast and performing machining centers is presented on the market: SPARK X is born

SPARK X revolutionises the traditional concept of Machining Center with a 3-axis configuration on the tool side and the workpiece to be machined housed on the rotary table fixed onto the base

A new concept of Machining Center is presented to the market, the RUMBLE line, dedicated to the 5-interpolating axes machining of large size workpieces

2010

In 2008 Mandelli is appointed with an important job for a line of RUMBLE machining centers for the machining of a 6-metre titanium work-piece of the new Dreamliner

The Financial Time issued on March 26, 2008 dedicates a whole page to this important success

2015

The SPARK line is completed with a new version, assembled in the recently renovated plant of Via Caorsana, named SPARK-Ti, specifically developed for the machining of hard materials, firstly titanium alloys

Mandelli develops the concept of a new innovative line of large-sized Machining Centers: the POWER line

2020

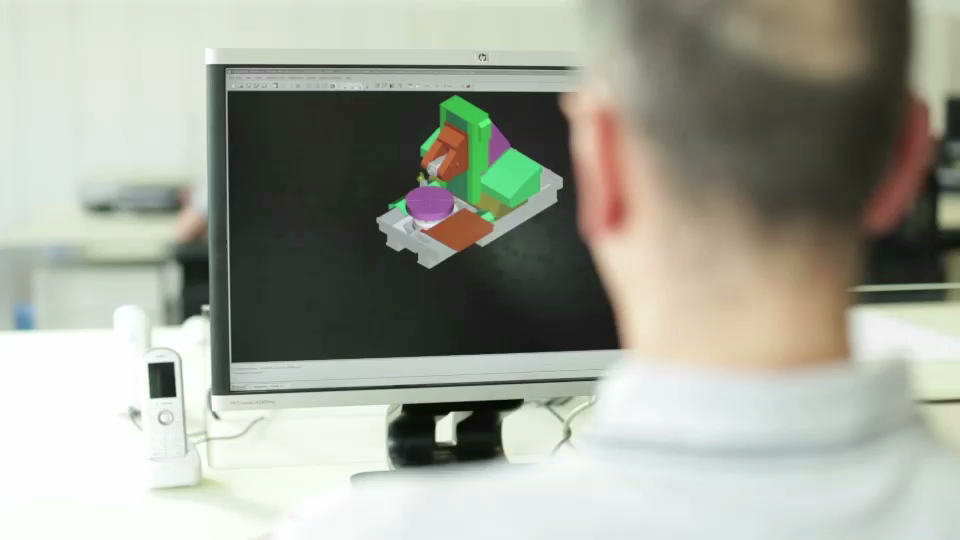

Horizon 2020

Mandelli gets into the world of Industry 4.0 with the iPum@suite4.0 package: predictive maintenance, automatic vibration damping, virtual reality to make maintenance easier, man/machine next-generation interface and FMS systems integration into the company control SW are the five pillars of Mandelli’s digital revolution.

2021

In June Mandelli becomes part of the Allied International Group